PHASE 1

DISCOVERY

1 WEEK

STEP 1

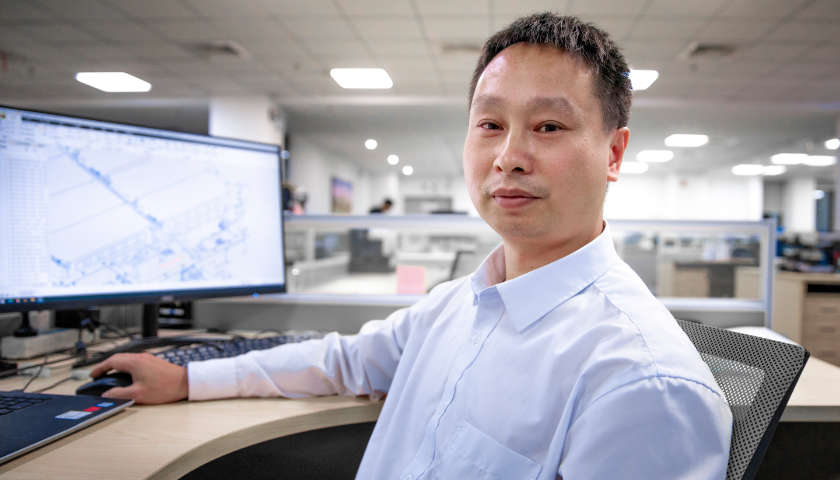

Requirements Definition

Kais Project Engineers communicate with customers in real-time, meticulously collect and organize relevant product information and certification requirements to speed up kick-off. To get started, simply fill an RFQ form or contact us about a customization project.

2 Working Days

STEP 2

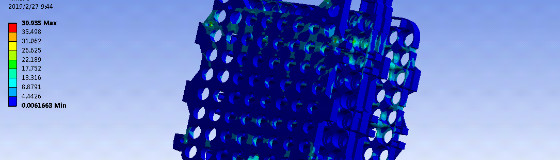

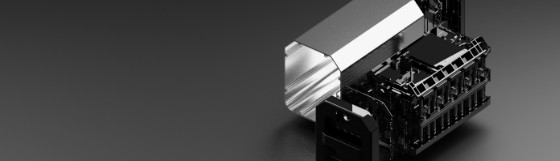

Technical Analysis

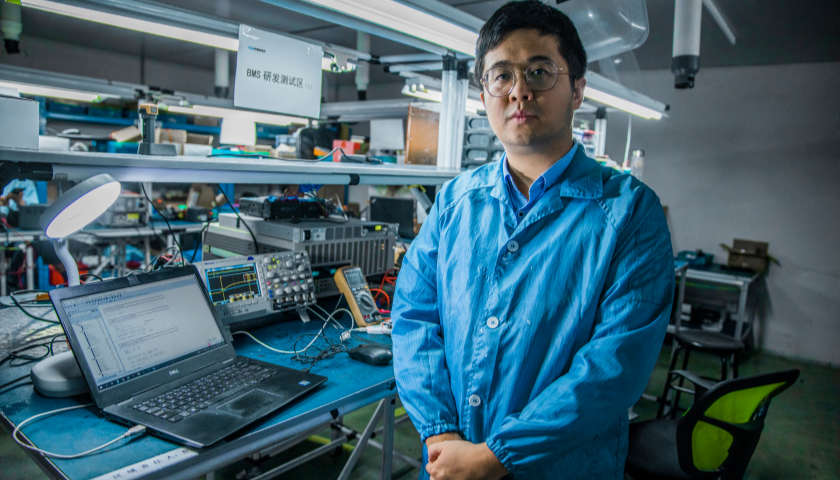

Kais consists of experts and veteran engineers with vast experience in various relevant fields. They will guide and advise on your project every step of the way. Selecting a suitable cell is a crucial first step to a perfect battery. Find out more in Kais cell research lab.

3 Working Days