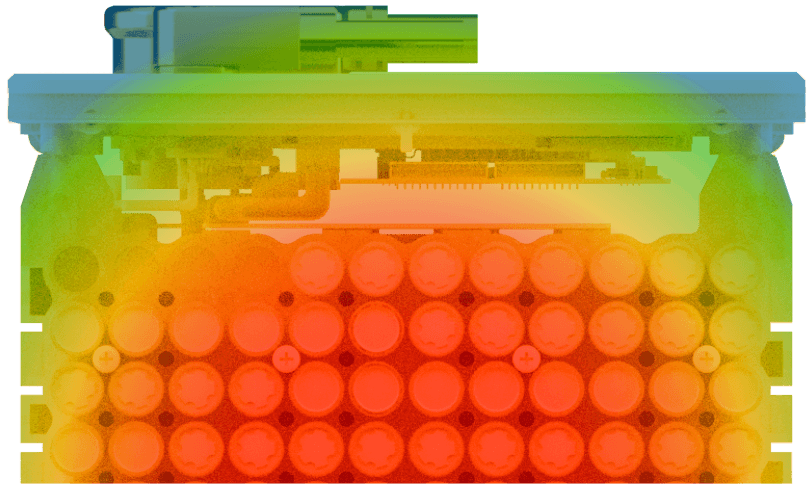

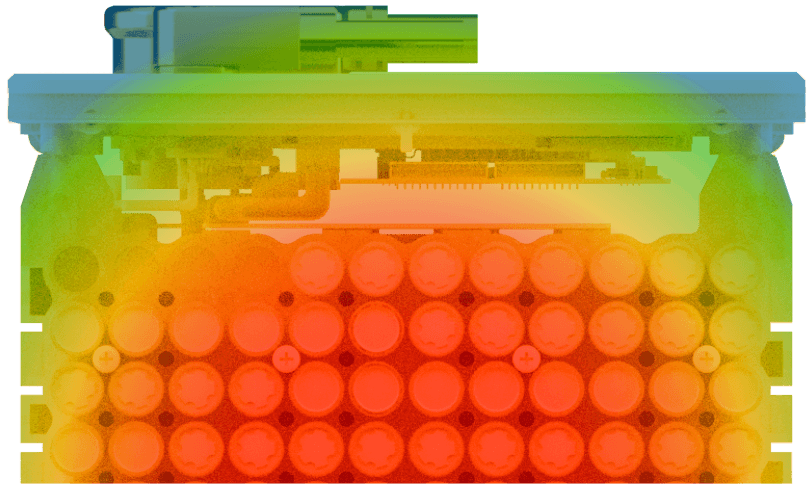

TEMPERATURE FIELD SIMULATION AND ANALYSIS

BATTERY PACK TEMPERATURE UNIFORMITY

Kais takes extra care in the reliability and consistency of our products. We use simulation tools to test our battery design against its actual operating environment and conditions and checks the design for any faults or flaws.

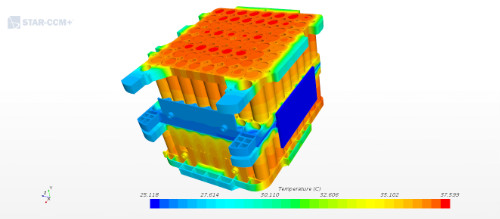

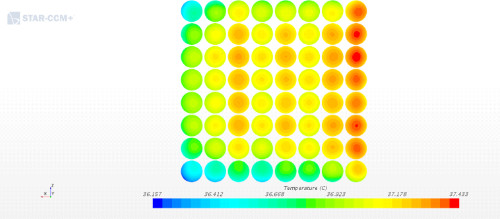

TEMPERATURE FIELD SIMULATION AND ANALYSIS

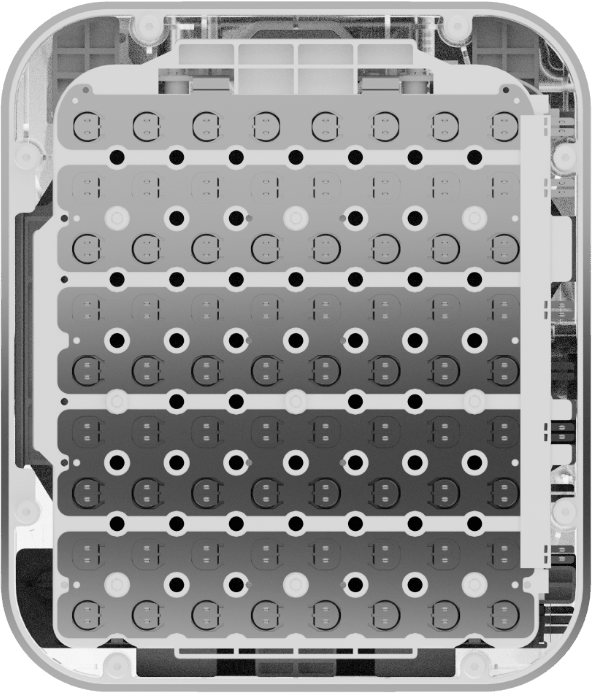

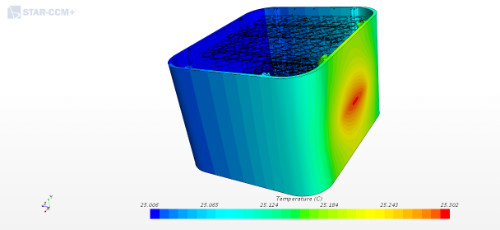

The uniformity of temperature within an enclosed battery pack is critical to the health and performance of the battery cells, it involves the simultaneous optimization of numerous parameters. Battery cells operating under different temperature settings will have different capacities and cycle life performance. Uneven dispersion of heat will cause some parts of the battery pack to overheat, causing the cells in those regions to lose capacity and break consistency with other cells in the battery pack, which will, in turn, affect the overall performance and cycle-life of the battery pack.

Our extensive knowledge of lithium-ion battery cells enables us to take the thermal factor into account during the design and development process, utilizing the finite element method to compare the temperature rise of different cells, and adjust our structure and material design accordingly. Experiments are then carried out on the prototype to ensure that the design is considerate of all scenarios.

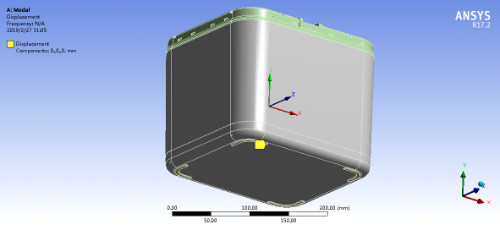

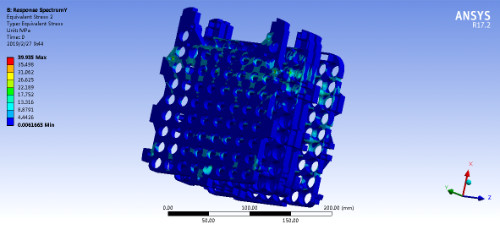

IMPACT AND OSCILLATION SIMULATION AND MODELING

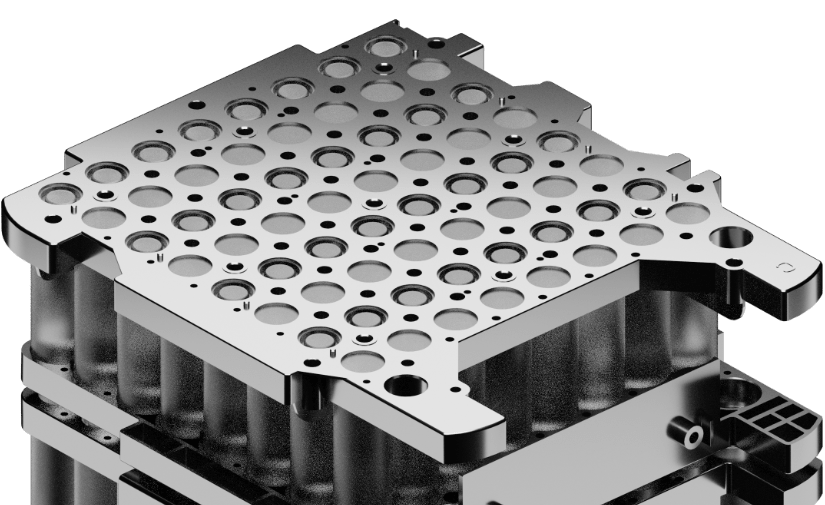

Before a design reaches the prototyping testing stage, we would digitally validate the battery and test it against various scenarios of abuse and misuse to identify the structural stress, fatigue, and yield points. We would then optimize our structural design based on accurate impact and oscillation simulation. This will shorten the development cycle and reduce the overall cost of development.

Supporting structure from all directions

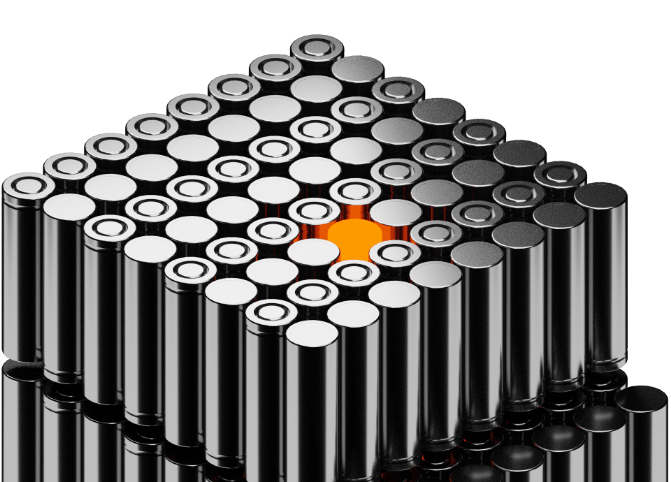

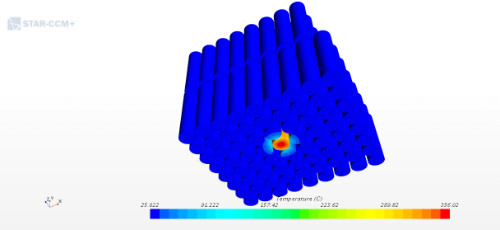

SIMULATIONS TO PREVENT THERMAL INCIDENTS FROM ESCALATING

We design and prepare for the worst. When thermal runaway happens in a single malfunctioning cell inside the battery pack, the internal temperature of the cell may reach up to 356°C, and the propagation of thermal energy will cause the adjacent cells to malfunction, leading to a chain reaction that will lead to fire or explosion. We use Precision Thermal Simulations to explore any structural flaws and potential weaknesses in a thermal runaway scenario and analyze the design of the electrochemical system and geometry of individual battery cells to strengthen the safety solutions and prevent thermal incidents from escalating.

The CCD solder joint detector is an automatic equipment for lithium battery processing, which has the functions of automatic positive.

CERTIFICATION SERVICE